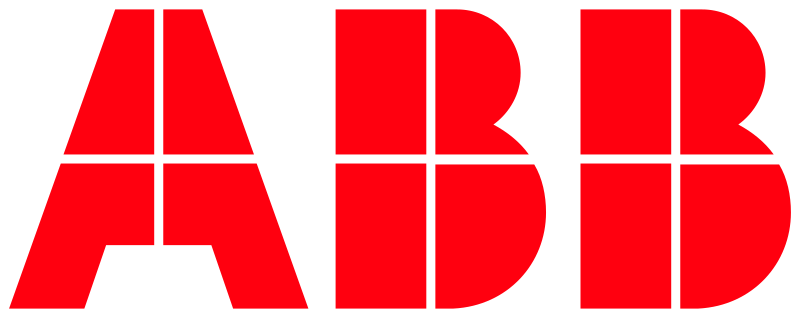

Press Automation :

This system provides complete automation loading & unloading press machines. Compared to manual production, this system makes production capacity and productivity too high due to its high speed and continuity. Most accidents occur presses as a result of research. These accidents are minimized by the robot.

The construction of a press cell usually requires the following equipment:

* Un-destacking unit,

* Centering units,

* Gripper,

* Electrical & Automation & PLC,

* Fence and operator protection equipment,

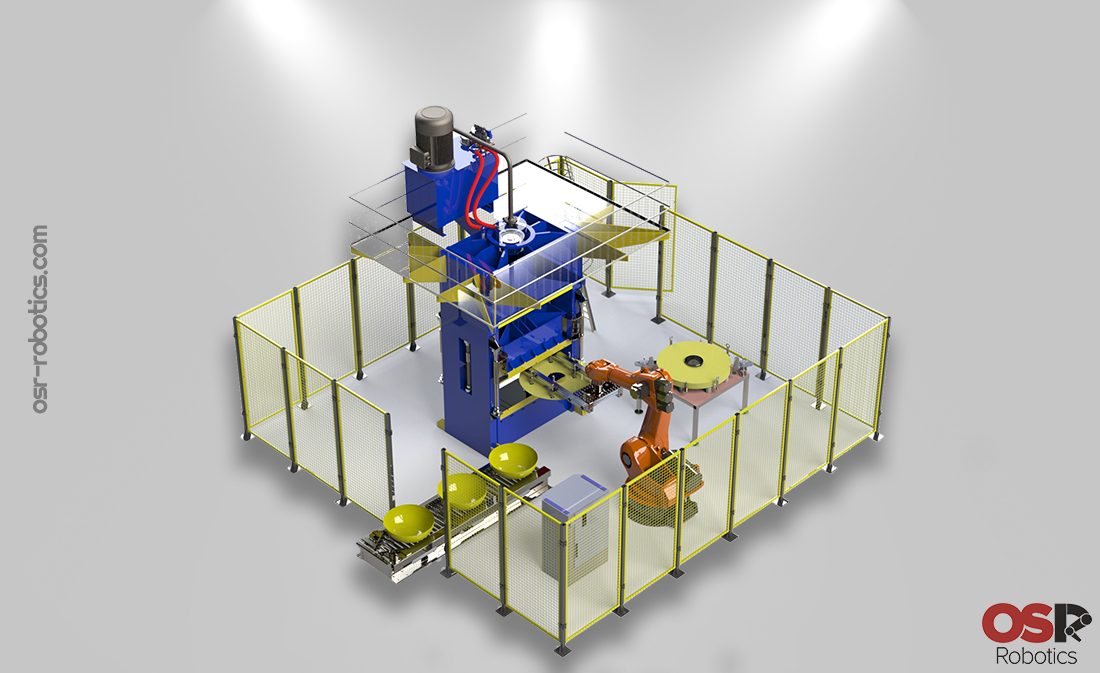

CNC Tending :

In the CNC Feeding Application robots place the products without damaging and sliding to different CNC machines where robot get them with gripper from feeding table. In the same way robots take the processed product from CNC and leaves them to separate stock places. In all applications there is a high level security. By considering the feeding table, robot can work non-stop. With that waiting time in CNC get decreased and production capacity reaches to highest level. In all processes robot and CNC machines will communicate.

The construction of a press cell usually requires the following equipment:

* Centering units,

* Gripper,

* Electrical & Automation & PLC,

* Fence and operator protection equipment,

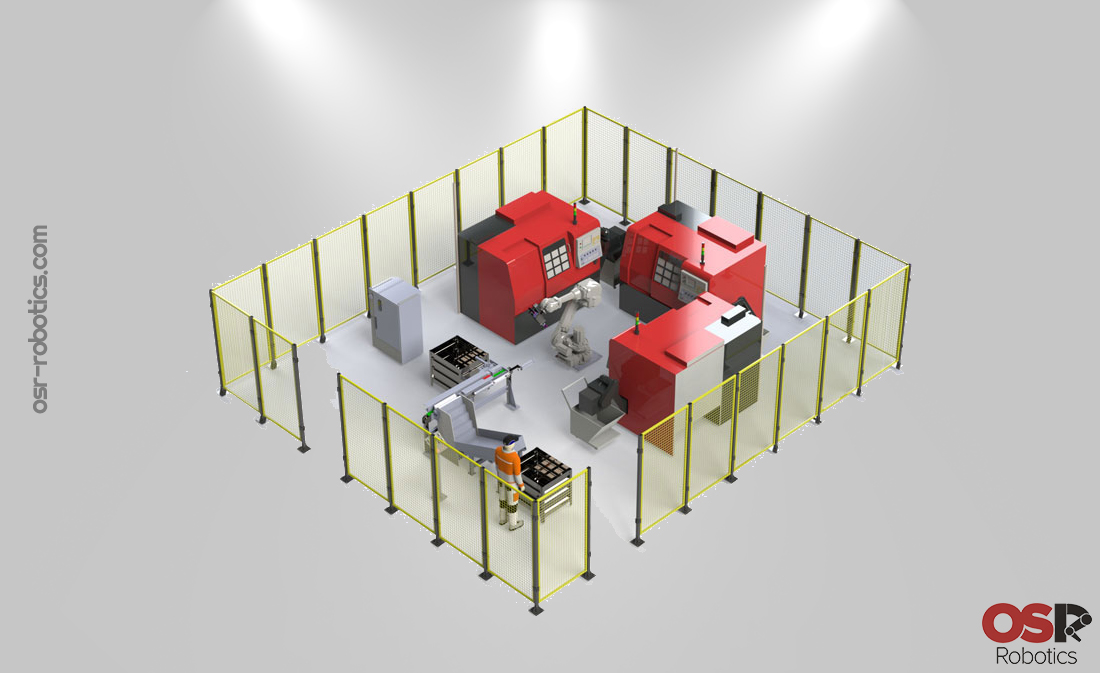

Press Tending :

The operator, who feeds the press manually, results in quality losses and longer cycle times. Particularly large and wide parts are hardly maintained.

The construction of a press cell usually requires the following equipment:

* Un-destacking unit,

* Centering units,

* Gripper,

* Electrical & Automation & PLC,

* Fence and operator protection equipment,